Parlors

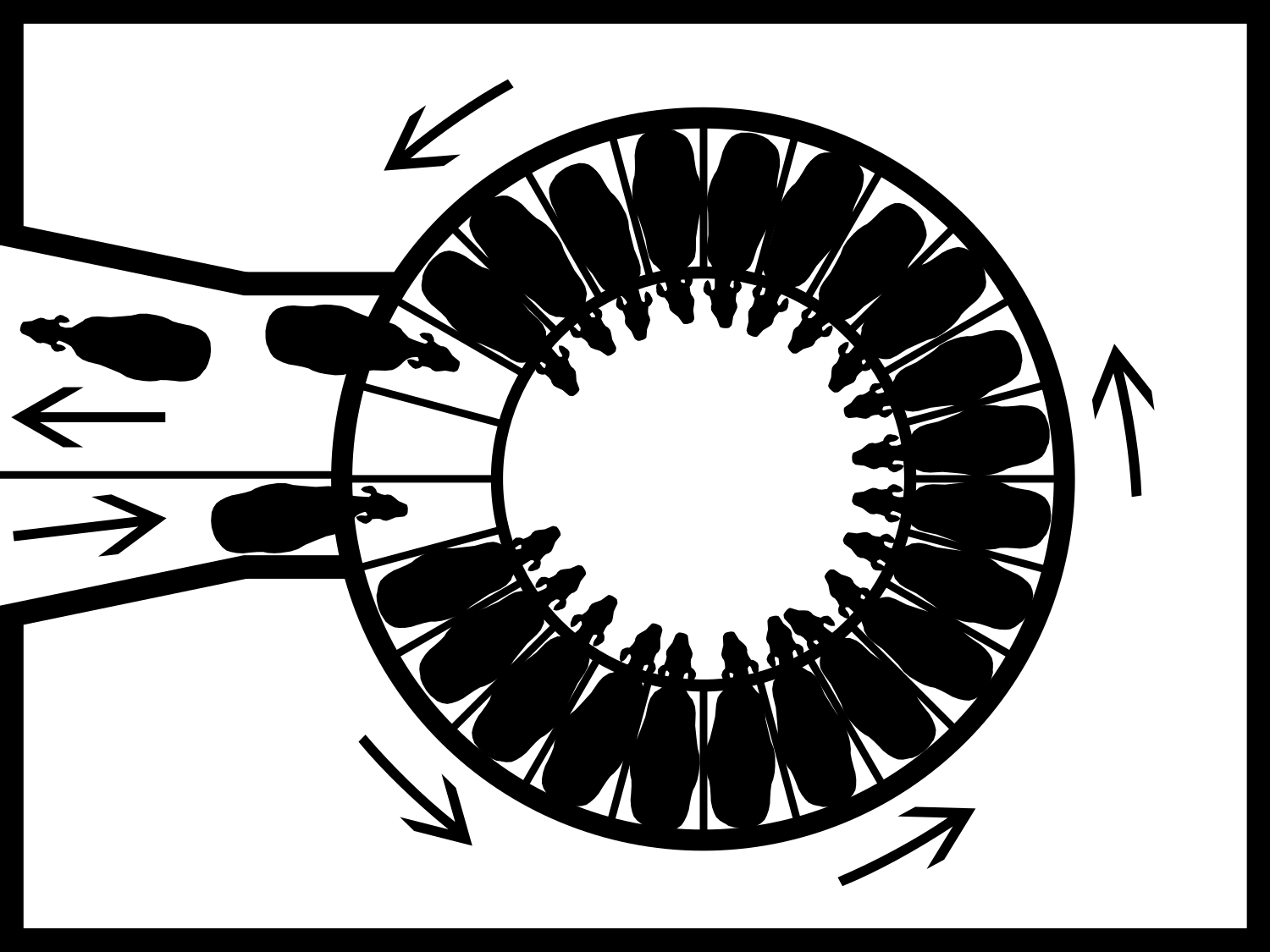

Rotary Parlors

In a Rotary Parlor the cow stands on a circular raised platform, allowing you to attach them from below. The platform rotates very slowly, allowing cows to enter and exit the platform at regular intervals. Cows are habitual animals which is very useful for carousel systems. The cows learn the entry and exit routines quickly and are happy to follow them. The low cabin design allows the cows to enter the platform faster and exit more easily. The milkers can concentrate on his or her main tasks. This means you will need less milkers for the same job.

DeLaval rotaries are among the most efficient and cost-effective solutions available to the modern dairy farmer. Rotary Parlors offer solutions to help you optimize your herd's milk yield and keep operating and labor costs low. At the same time they provide a comfortable and safe environment for cows and operators. We offer Rotary Parlors for dairy farms of all sizes. If you're not ready for all the bells and whistles, you can add automations to your milking system as your budget allows. Our team is happy to answer your questions and make our professional recommendations based on your unique needs and your herd size.

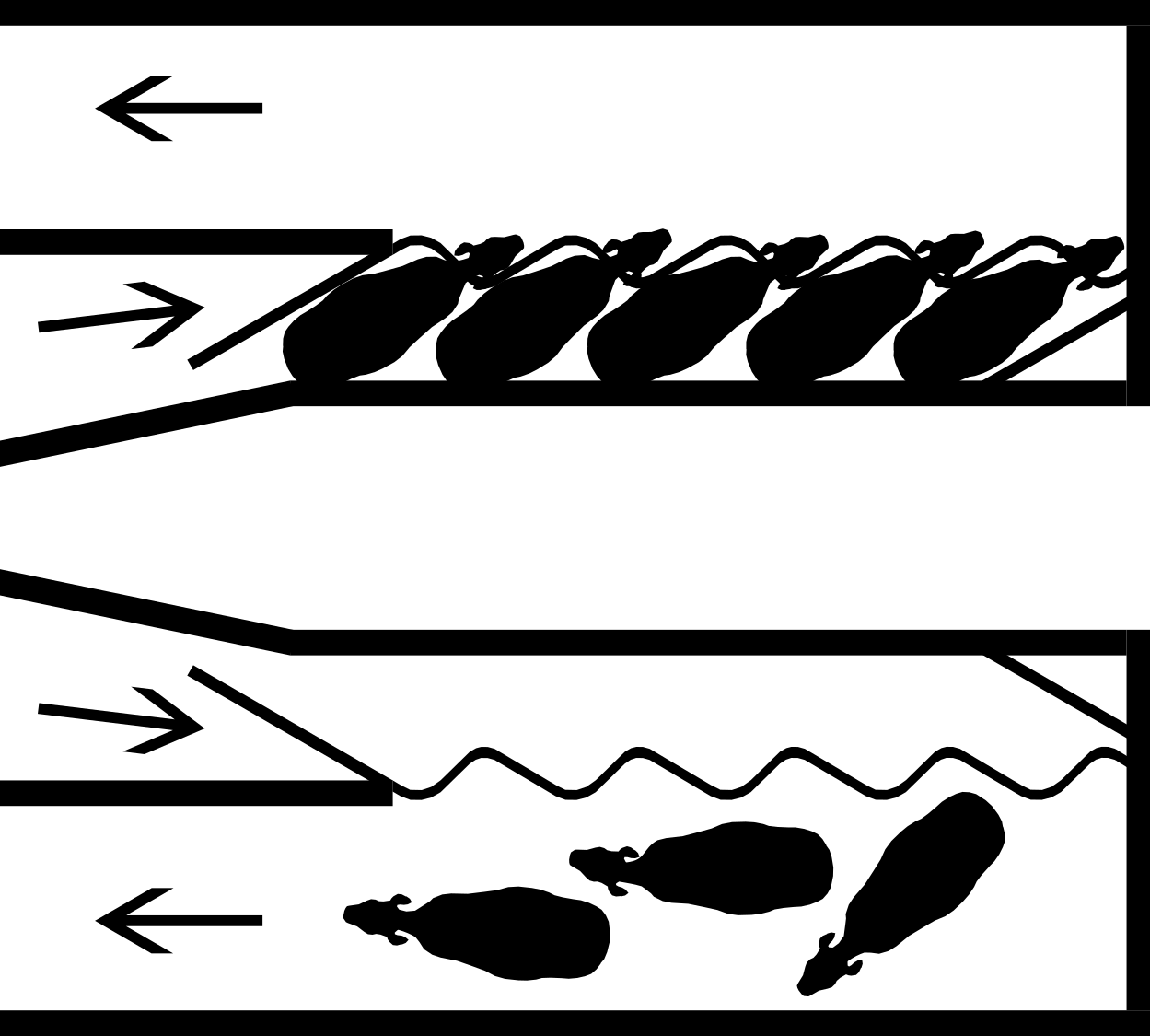

Step-Up Walkthrough Parlors

In a Step-Up Walkthrough Parlor, each cow is led to her stall and steps up onto a concrete pad, while the milker steps down into a small pit between every pair of stalls to prep and attach the cow on either side of the pit. When a cow is finished milking and has been post-dipped, the special head-lock in a Step-Up Walkthrough Parlor opens up and she walks through it to the exit alley. This feature makes the Step-Up Walkthrough Parlor distinct as cows are led in but do not have to be led out again, saving you time and making your process more efficient.

The Step-Up Parlor may not be what most dairymen or women think of first when they think of a typical Parlor, but it is a great option that offers a low-cost method of milking faster and more efficiently than in a Tie-Stall Barn.

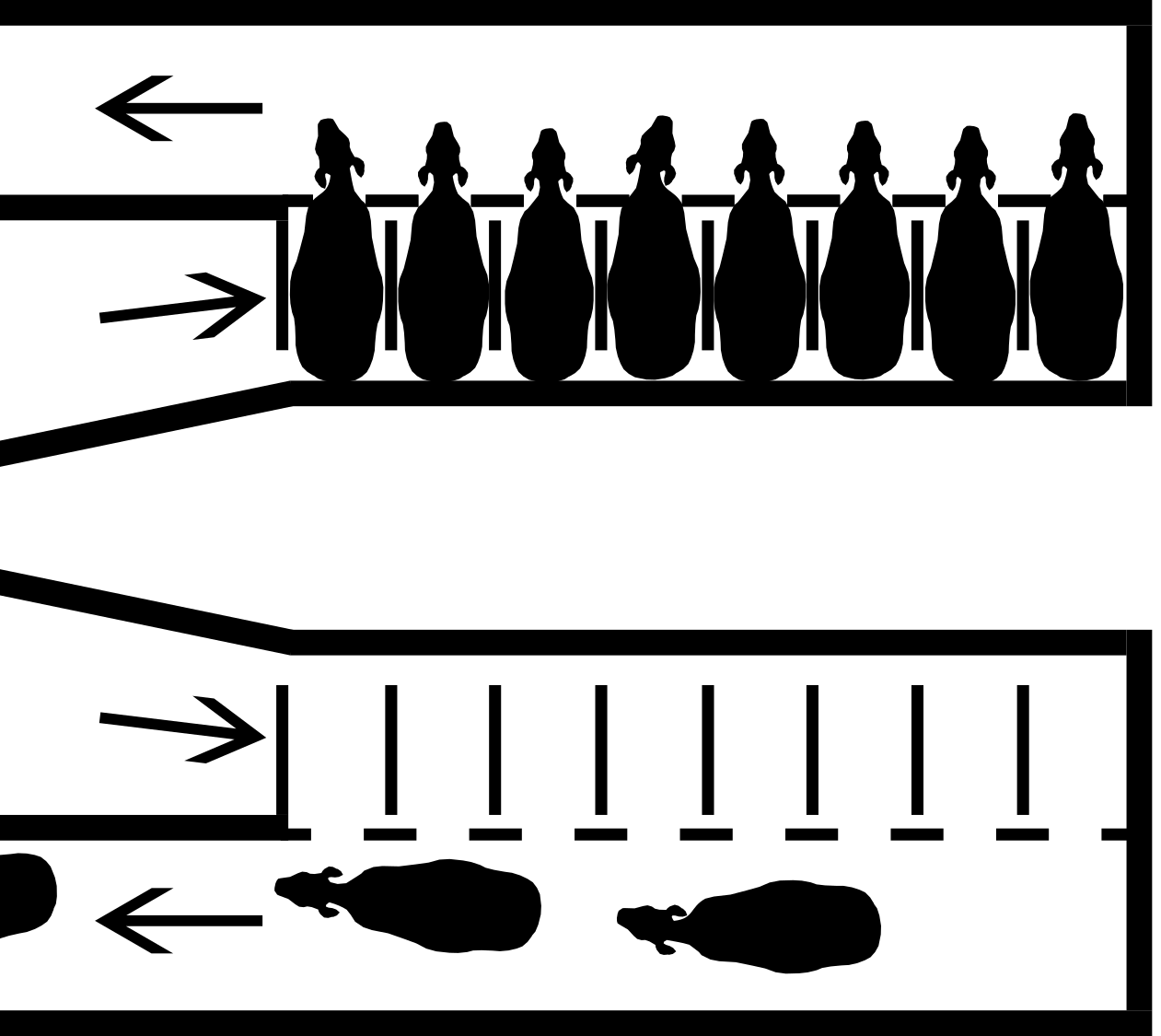

Parallel and Herringbone Parlors

The Parallel and Herringbone Parlors are the conventional Parlors that most people think of with a large pit in the middle where the milkers and milking equipment are and with the cows entering on either side of the pit. The main differences have to do with the angle at which the cows are presented to the pit. In a Parallel, cows are lined up perpendicular to the pit and the cows are prepped and attached from the back of the animal, between the rear legs of each cow. The Herringbone, on the other hand, has cows presented at an angle to the pit and prep and attachment are performed on the side of the cow instead of through the back legs.

Conventional Parlor Styles & Layouts

Slide title

Write your caption hereButton

Basic Parallel Parlor Layout

Slide title

Write your caption hereButton

Basic Herringbone Parlor Layout

Slide title

Write your caption hereButton

Basic Rotary Parlor Layout

Take a Virtual Tour

Morning Star Dairy – DeLaval Parlor P500

Sassy Cow Creamery | DeLaval Rotary PR3100HD – 40 Bail Tour

Vierra Dairy Farms – DeLaval Parallel Rotary PR3100HD – 80 Bail

Talk to a Team Member

Tell us about your needs and we're happy to answer your questions or provide a quote!

Sign up to our newsletter

We will get back to you as soon as possible

Please try again later

Tell us about your dairy farm.

Quick Links

Contact Us

Southeastern PA:

1044 Main St. Blue Ball, PA 17506

(717) 354-8030

Northeastern PA:

391B Harrison Rd. Orangeville, PA 17859

(570) 925-6939

Email Us: info@jbzdairy.com